SURF GREEN

Marko Foam Blanks

KJA Designs Inc. proudly uses Marko Foam blanks. Marko Foam is a long-standing California company constantly advancing its mission of providing an extensive blank catalogue to the water sports industry. Marko Foam’s company goal is to provide a versatile blank catalogue that consists of a variety of high quality, 100% recyclable material in multiple blank sizes, giving the surfer an ample assortment of choices.

Over the past few years, Marko Foam has introduced new viable materials into the surfboard-manufacturing world. Its long-term plan is to refocus the surfboard manufacturing process of the past 45+ years to a new approach of using environmentally friendly and innovative materials. Marko Foam’s unique approach coupled with decades of foam knowledge has helped it put together this versatile catalogue of core materials for all types of surfboards. The various materials offered in the Marko Foam catalogue are all manufactured with its clean, high pressure molding process that results in a tight, strong, durable core that stays lively long into the board’s life.

Marko Foam feels there is a place for this exciting new product to thrive in the surf industry.

Manufacturing

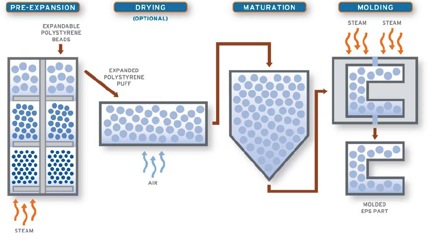

EPS is produced through the heating up of water in boilers to produce steam. This is then used to expand the plastic beads and fuse them together in molds. This process has a very low impact on the environment due to the low overall atmospheric and liquid emissions. Additionally, this process has very low water consumption, most of which can be reused many times. Also, there is no solid waste produced during the manufacturing of EPS. If solid waste was produced, it could be used again since it is 100% recyclable.

Toxicity

Molded EPS is non toxic and completely inert. Its basic chemical makeup consists of carbon, hydrogen and oxygen, elements found in wood and other organic materials. It is also completely absent of any nutritional value, so no fungi or microorganisms can grow within EPS.

No CFCs

EPS does not damage the ozone layer since it does not use CFCs or HCFCs in the manufacturing process.