HYDROFLEX

Superior Performance & Responsiveness

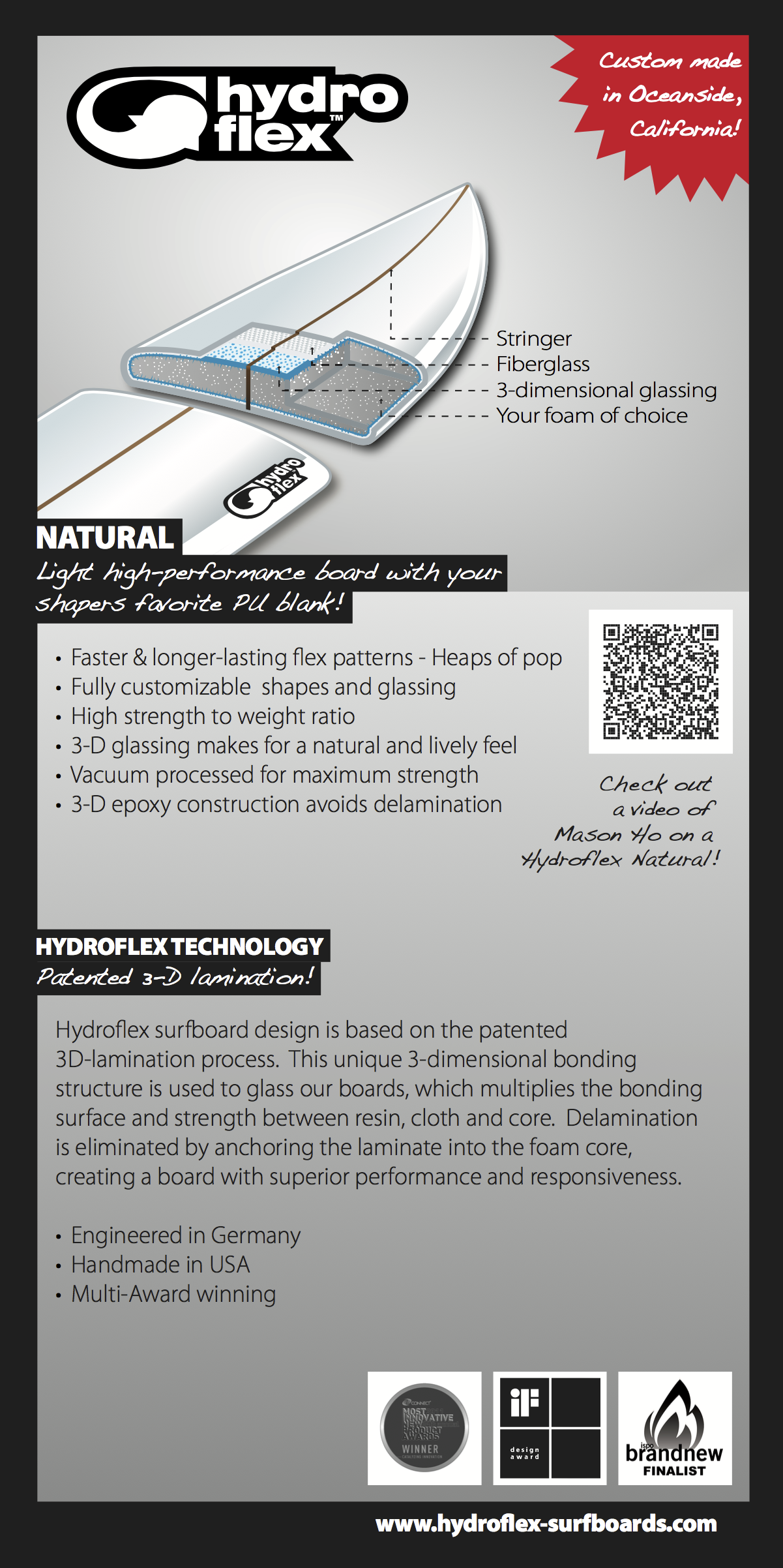

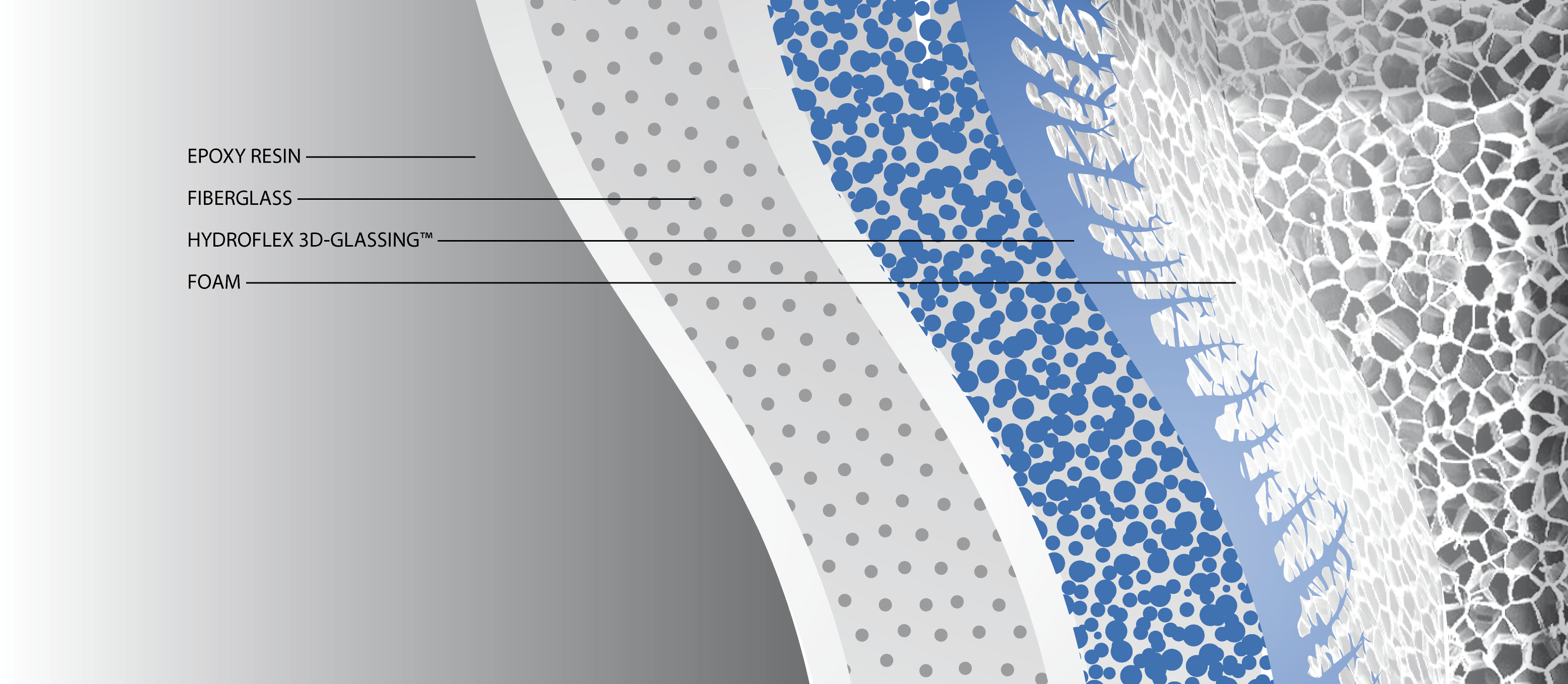

KJA Designs Inc.’s surfboard construction is based on Hydroflex’s patented 3D-Glassing™ and lamination process. This unique 3-dimensional bonding structure is used to glass all our surfboards, which multiplies the bonding surface and strength between resin, cloth and core. Delamination is eliminated by anchoring the laminate into the foam core, creating a board with superior performance and responsiveness.

All Hydroflex-glassed boards are made with epoxy resin for a natural and lively feel. Epoxy resin is a lighter and stronger resin compared to standard polyester resin and allows for twice the flex before cracking. The other benefit of Epoxy resin is the molecules will not break down over time. This process gives you the highest strength to weight ratio available and is coupled with excellent flex characteristics, as well as completely customizable shapes and glassing.

This process was developed in Germany after years of research by surfer and shaper, Bufo. With the idea of plant structure in mind, he engineered this process to produce high-performance surfboards with proven flex characteristics. Every KJA Designs Inc.’s board comes with 3D-Glassing™.